1-800-846-8399

sales@vintex.com

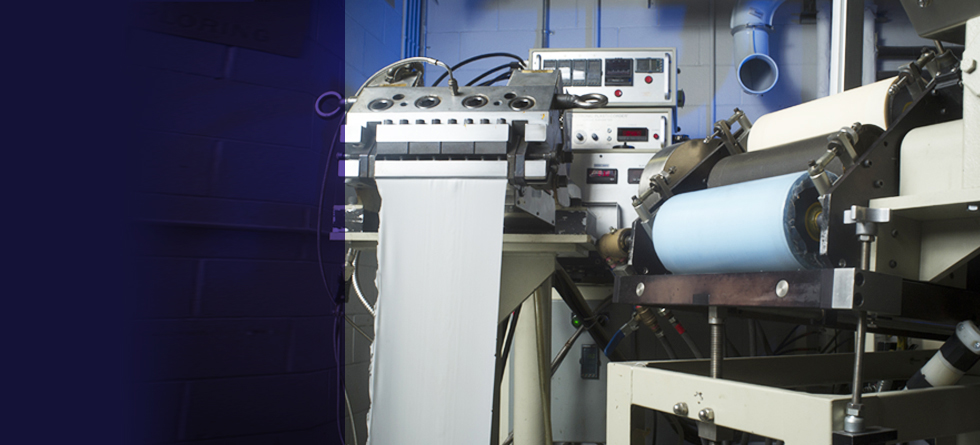

Integrated

Manufacturing

in-house compounding

through extrusion coating,

Vintex does it all in our

world-class manufacturing

facility in North America.

Polymer

Coated Fabrics

process coats a variety of

polymers into highly durable

coated fabrics across many

end markets.

Product

Development

development facility enables

product ideas to become

commercial successes in

record time.

Customer

Service

service is a driving force

behind Vintex, working

hard everyday to

exceed expectations.

Making a Difference for More Than 60 Years

For over 60 years, Vintex Inc. has specialized in manufacturing coated textile fabrics to meet the most demanding needs of our customers. Vertical-integration production processes and state-of-the-art technology allows us to offer unparalleled product quality of custom knit-base textiles, compounding, extrusion coating, colour matching and inspection of finished product. This is paired with an exceptional customer service team dedicated and ready to meet your specific challenge.